Contains the skills and experiences

of a Korean Master Hand

-

1 The first in Korea

The First power-saving low-temperature

high-humidity Inverter Dough Conditioner -

2 Premium baking machine

Premium baking machine that controls

everything of dough -

3 Build own production line

Build your own production line and have the

different types of models you want

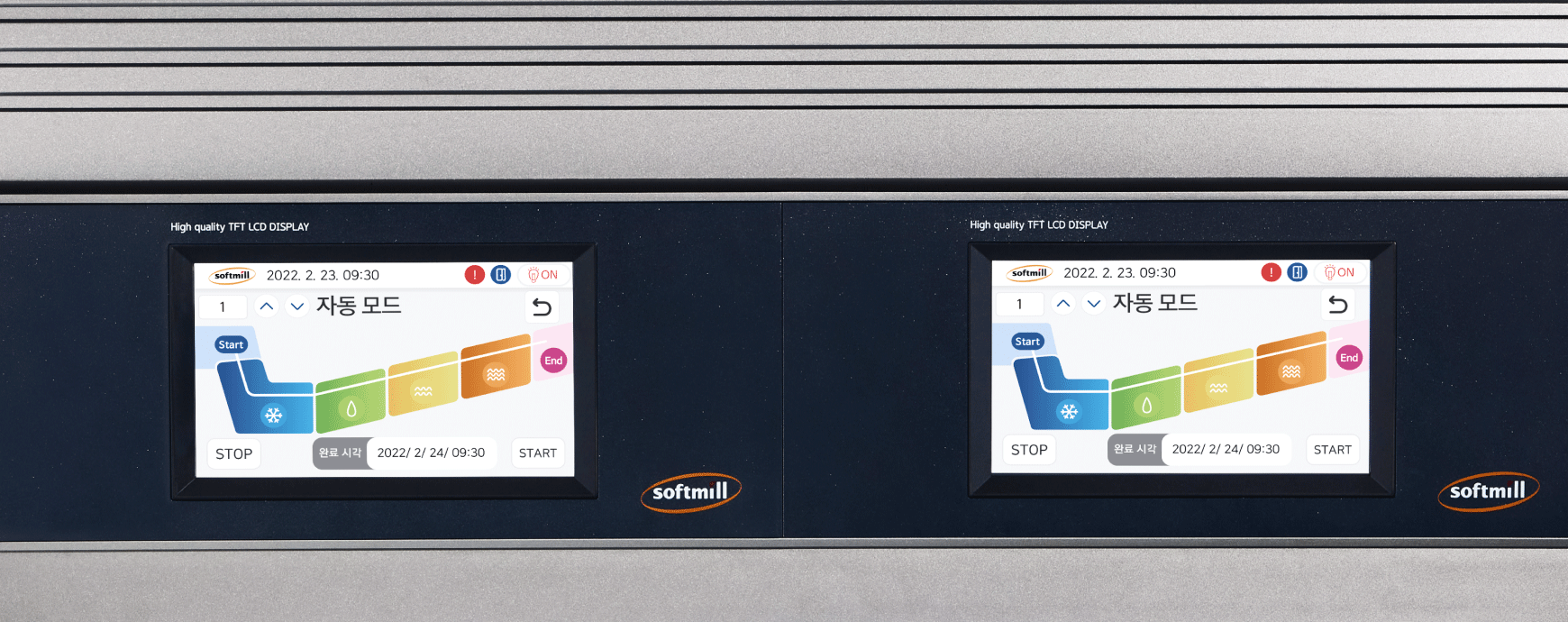

Smart control system

High-performance CPU central processing unit

High-performance memory is installed to notify users of the operation status and error information, while expressing the entire process from freezing to thawing and proofing using graphics.

TFT LCD touch-type controller

The 7” LCD-TFT liquid touch method controller offers intuitive and easy operation.

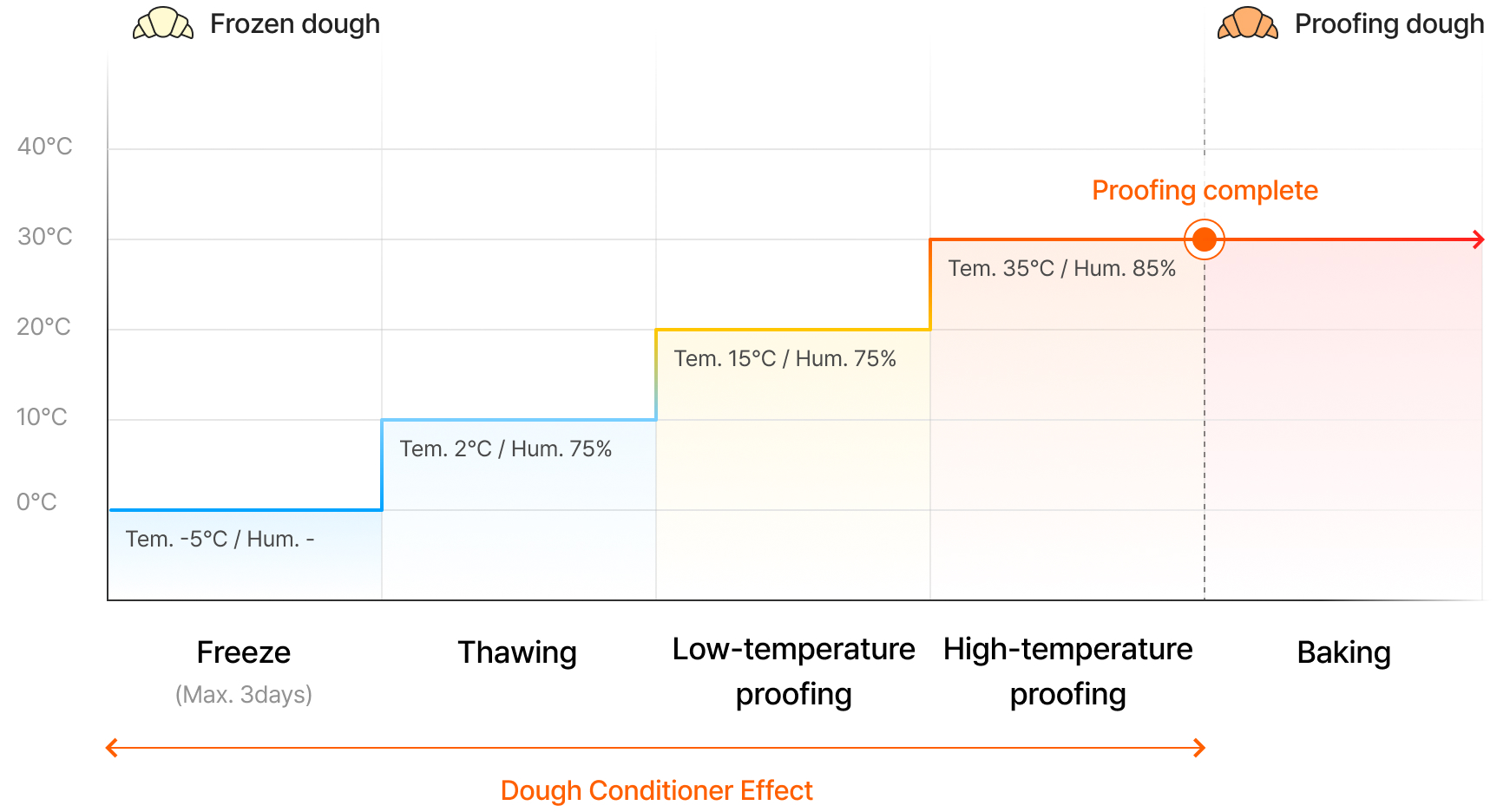

Inverter compressor

Freeze cycles control temperature settings precisely through PWM control signals to maintain optimal cold air circulation state and reduces energy usage by more than 25%.

Digital temperature and humidity control sensor

Temperature and humidity in the storage are detected and analyzed in real-time through digital communication signals to maintain exact temperature and humidity.

Optimal process

system

Design registration 30-0624993

Air circulation system

Precise temperature

control system

Patent registration 10-2184709